I can't see anything, I hear everything.

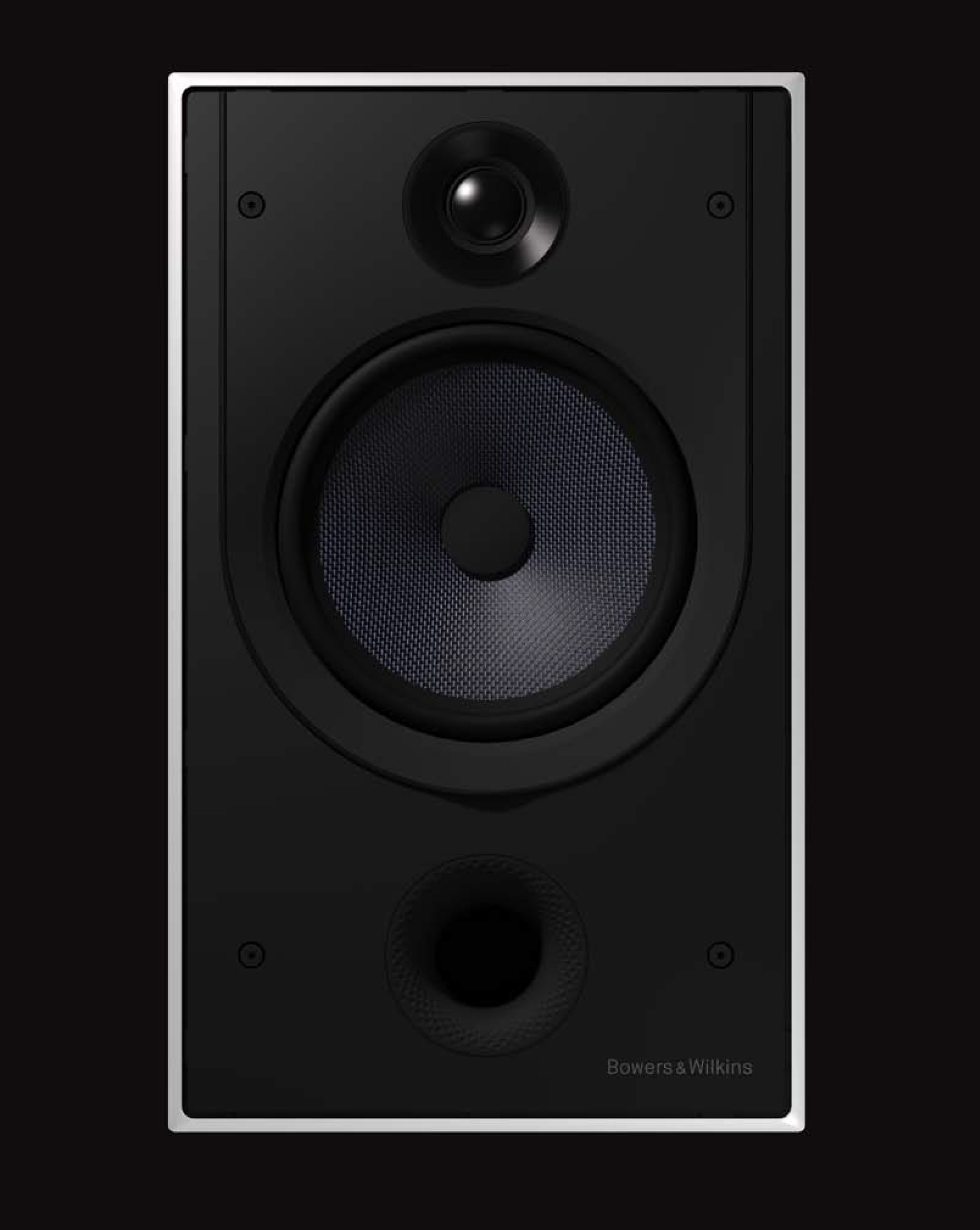

The new Bowers&Wilkins CI800 Series Diamond Series Custom Mounted Speakers are designed for discerning customers who demand high-fidelity sound and home theater sound for speakers that require minimal space. This special range of in-wall and ceiling-mounted speakers features all of the key sensor technologies developed for the world-renowned 800 Series diamonds, including the Diamond dome tweeter, the Continuum IF driver and the Aerofoil bass cone. Despite the significant performance improvements, each new model is suitable for the rear box and aperture of the outgoing CI800 series, so owners can easily upgrade to the significantly improved performance offered by the new series. The result is an excellent level of performance that again increases the standard for custom-installed speakers.

technology

Back box

The CL800 series diamonds have been developed to fit the existing rear box, making the customer's shipping model easy to upgrade. Full-MatrixTM support for extra rigidity and improved performance. The back box is a two-wire cable that is electronically connected to the baffle via a multi-pin connector.

diamond

For the first time, we integrated the diamond dome weeder into a custom mounted speaker. The exception is that, although very light, but incredibly rigid, the diamond dome provides jets with no distortion and high pitch.

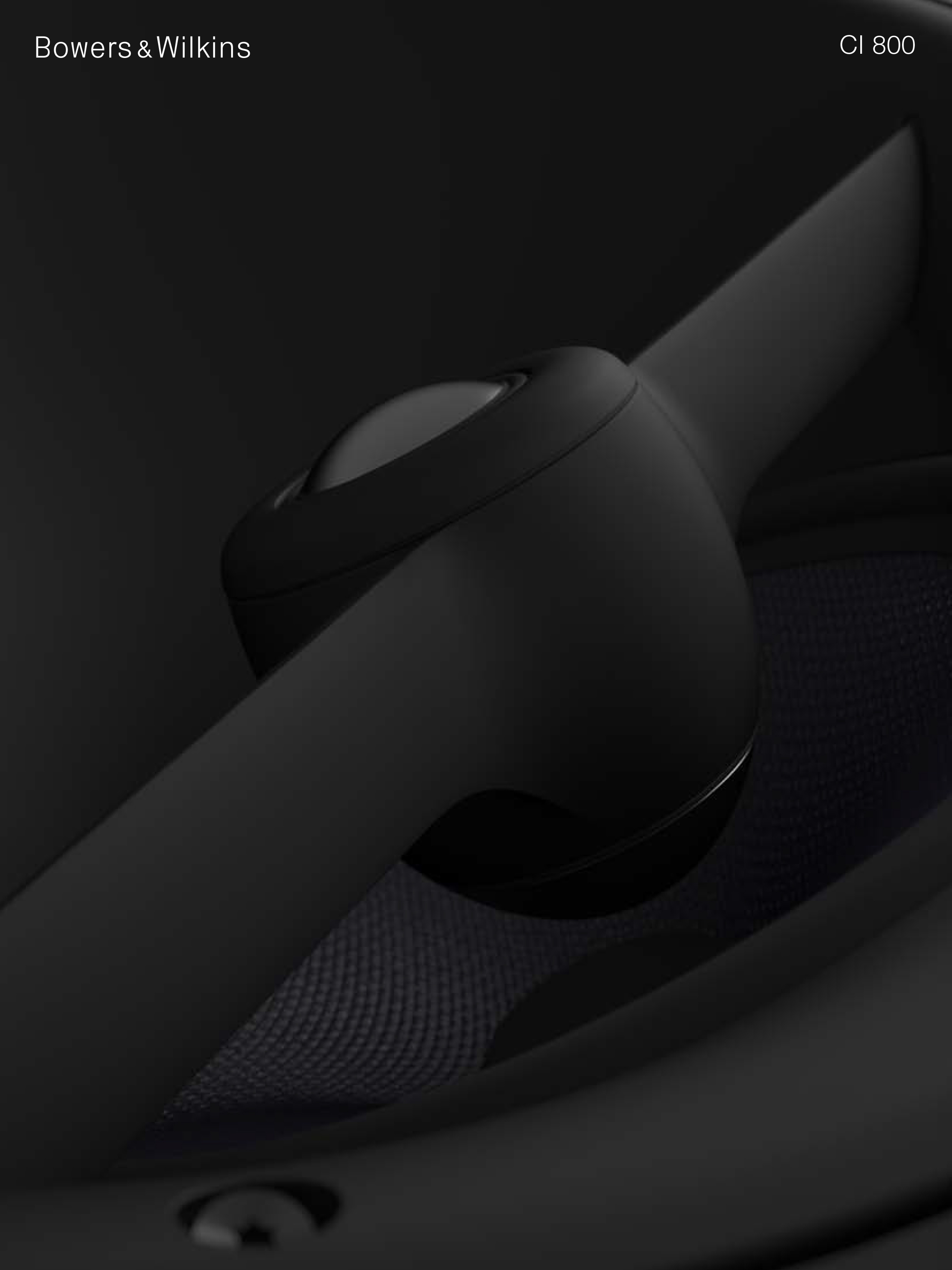

Continuum

The Tne C800 Senes Diamond features the new ContinuumCone, our superior new IF drive technology. The results of an eight-year research and development project were introduced in our flagship 800 Series diamonds and provided the original mid-range performance.

airfoil

The first developed 800 Series Diamond Aerofoil offers incredible bass performance. The ultra-light but extremely hard wing design combines a computer-optimized form with a carbon fiber sheath and a lightweight composite foam core to ensure precise, sharp bass.

Decoupling

The Diamond dome tweeter and IF drive unit in the new CL800 series Diamond are completely separate from the main body of each speaker in a similar manner to the drive unit in the 800 Series Diamond. This minimizes the effects of resonance through the baffle, allowing each drive unit to work and produce a clearer, more accurate sound.

specification

|

CWM8.3D |

CWM8.5D |

CCM8.5D |

description | 3-way wall speaker | 2-way wall speaker | 2-way ceiling speaker |

Technical characteristics | Aluminum mini baffle can burn through a 90 degree diamond dome, Nautilus TMtube loaded tweeter, Ti resonant plug, flow port, MFST M intermediate frequency unit, carbon wing bass drive |

Diamond dome, Nautilus Mtube loaded tweeter resonant plug flow port | The aluminum tweeter wing can be rotated by an aluminum baffle for “tip toe and dome”. Nautilus Mube loaded tweeter resonant plug flow port |

Drive unit | 1X O25 mm (LIN) diamond dome. Nautilus TM tubular tweeter 1X O130 mm (5 inch) continuous IF driver 2 xO180 mm (7 inch) wing type bass driver | 1 O25 mm (LIN) diamond dome. Nautilus M tubular tweeter 1 O180 mm (InContinuum cone/intermediate drive with anti-resonant plug) | 1X O25 mm (LIN) diamond dome. Nautilus TM tube loaded tweeter 1X O180 mm (in) continuous cone bass IF driver with anti-resonance plug |

Bowers Wilkins

For decades, the innovative inventions of the Bowers-Wilkinsstein Research Institute have influenced the way loudspeakers are designed and built around the world, and the sound quality has improved, regardless of sound quality, including top-level studios. London's Abbey Road at Ci 800 Bowers. Wilkinson introduced some of the extraordinary techniques that have never been seen in wall and ceiling speakers. Provide original, high-fidelity sounds from speakers that disappear into your environment.

The real Sound Bowers & Wilkinsis is the name of the world's most respected speaker. These include their Nautilus Reference 800 Series Diamonds. And the CT800 for the ultimate home theater experience

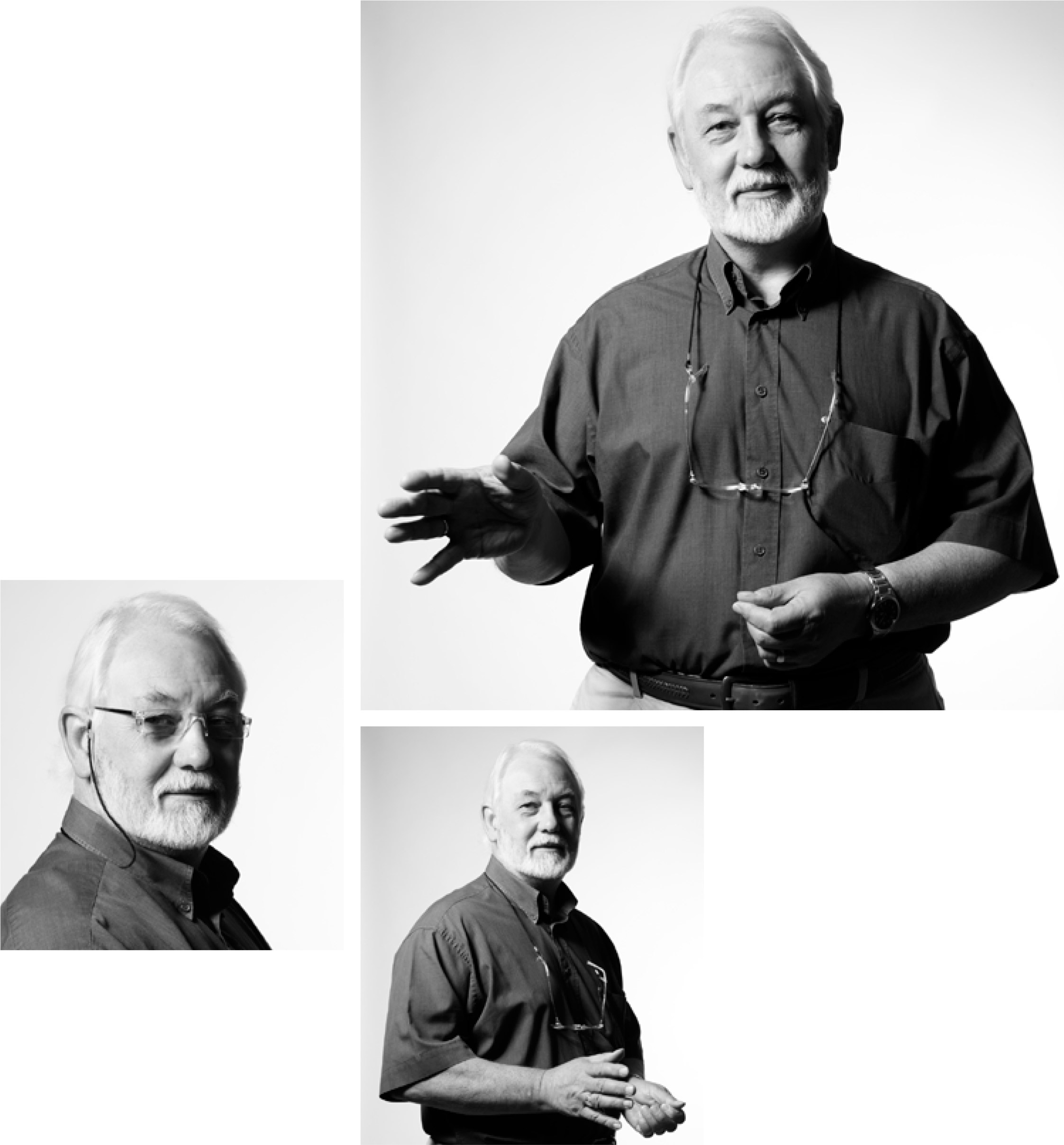

Interview senior development engineer John Dibbd discusses the challenges of developing CI 800

What are the challenges of integrating the 800 Series diamond technology into a custom installation? What are the challenges of integrating the 800 Series diamond technology into a custom installation?

The main challenge is the need to mount the system into a wall approximately 100 mm (3.9 inches) deep and approximately 200 mm (8 in) deep ceiling cavities. Although most high frequency and midrange drive units do not have depth issues, specialized hollow bass drives are required in wall applications and extensive development is required to ensure they match the printer. The performance of deeper box speakers. A rear enclosure that is mounted in a wall or ceiling must also be provided to determine the working volume of the system. For interior walls, this must have a relatively thin wall structure so as not to take up valuable cavity space, and a significant amount of time has been used to optimize the material and internal support to achieve the hardest structure. Finishing and dimensional accuracy require the use of baffles in wall/ceiling systems and the use of more retaining walls. A material such as wood or medium density fiberboard. It took a while to find the ideal material that provided the required precision, strength and acoustic performance. Ultimately, the material that best suits our needs is a highly glass-filled thermal resin.

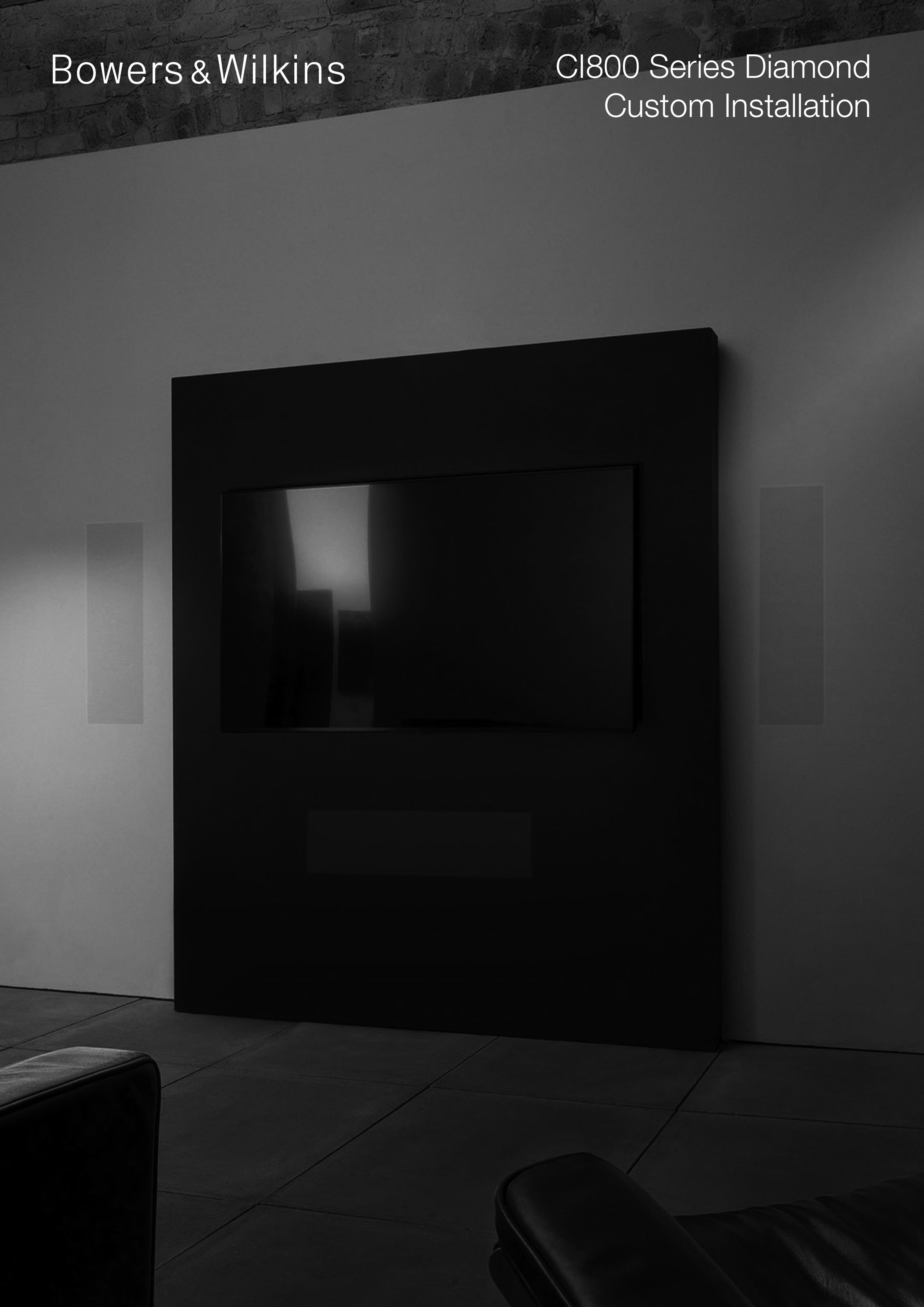

What are the advantages of interior and ceiling design?

There are two real advantages to installing a suction cup that is flush with a wall or ceiling. First, there are no discontinuities, such as the corners of traditional cabinets, so the diffraction effects used by these edges no longer exist, and the walls behind the speakers do not have typical reflections. Second, speakers mounted on large surfaces work more efficiently at low frequencies, providing different characteristics for box speakers in free air. This effect can be exploited in a properly designed bass driver to provide a larger headrest with lower distortion.

How do you face the challenges of any shortcomings?

There are two disadvantages of the wall system. First, the wall structure is uncertain. It may be a masonry structure, very good, or it may be a lightweight wood/gypsum board structure that vibrates itself and deforms the sound. To solve this problem, we attempted to minimize any vibrations that reach the wall by isolating the drive from the baffle, and secondly, there is a practical limit to the available capacity in the rear casing, which can limit the low frequency expansion of the system. We use a specially developed back box to deal with this problem. The main disadvantage of ceiling placement is that the listener is much farther away from the axis. For stand-alone and wall-mounted speakers, the position of the earpiece is relatively clear relative to the speaker, usually only a few degrees from the front axle. In sharp contrast. Someone is facing the ceiling speaker, which may typically deviate from the axis by 60 degrees, where the response of the river changes significantly. To counteract this, our ceiling system inserts the drive into the ceiling at an angle of 30-45 degrees.

What are the different challenges you face when designing ceilings compared to wall-mounted speakers?

When using CI, you need to ensure that the sound is spread as wide as possible, and experience has shown that coaxial drives work best. Previous systems also used mechanically rotating high frequency units and variable drive equalization to optimize response at different angles. However, any change in driver position will result in all changes in performance, so for purists like CCM85, any changes in driver position are excluded. Drivers are designed to be widely and evenly dispersed to give minimal changes within a defined listening window. Even if the entire baffle can be rotated without affecting performance, some flexibility can be obtained to align the center of the window with the listening position.

Dr. John Dibb Senior Development Engineer, Bowers & Wilkins

technology

Carbon ring tweeter

Our aluminum dome tweeters have a decomposition frequency of 30 kHz and have already made the sound quality well above the upper limit of hearing. But, inspired by what we learned about diamonds, we want to see if we can do better. The result is a new high-pitched dome that first appeared in Bowers Hillkins' high-end PMI speakers. By supporting the dome with a fiber-wound carbon fiber ring, we increase the split frequency OA aluminum to 40 kHz. As a result, a pleasant high pitch can be heard in the custom-mounted speaker.

cross

The jumper structure illustrates the quality of the speaker. What you are looking for is simple. The rule is that the better the design of the drive, the simpler the Crossover design, and the quality of the C 800 drive allows us to use the same special hand-selected components in the flagship 800 series, making the speaker the easiest to produce. One of the best Level Crossover. S diamond

Double bass

Custom-mounted speakers offer two advantages and challenges for low frequency output. The nature of the baffle to the solid wall of the rock provides a stable platform for the operation of the drive. However, since the drive must be installed in such a cavity, a specially designed low offset drive must be designed. The dedicated woofer on the 800 series diamonds uses carbon fiber-reinforced Rohacell cones, while Bowers & WilkinsFlowport technology significantly reduces the low-end unnecessary tilt effect. No matter what you listen to in the room, the result is a strong bass.

Castration

Ready to act

Matrix has long been a technology of Corebowers-Wilkins, and together with the cl 800, it was first used to increase the rigidity of custom-installed products.

One of the biggest challenges for Bowerswillkins engineers in converting the high performance of the 800 Series diamonds to the ICI800 series is to ensure the performance of the wall-mounted back box and any traditional Alfree upright speaker cabinet. A lot of time is spent optimizing the material to get the structure as hard as possible and listening to the results. The trunk also features a full Ymatrix support for added rigidity and improved performance. The installer is also listening, so the trunk is routed to the terminal panel via a two-wire cable. The trunk is also electronically connected to the bezel via a multi-pin connector.